System-in-Package and Multi-Chip Modules

Accelerate edge computing deployment with trusted, high-performance system-in-package and multi-chip module solutions integrating the latest in commercial silicon technology

Accelerate edge computing deployment with trusted, high-performance system-in-package and multi-chip module solutions integrating the latest in commercial silicon technology

Mission-critical applications at the tactical edge drive demand for low-latency processing in ever-shrinking form factors, leading to an emerging need for compact, high-performance signal processing solutions. We partner with high-tech industry leaders to make the latest in commercial silicon profoundly more accessible to the aerospace and defense industry. Our system-in-package solutions integrate this silicon with customizable chiplets, plus the added benefits of advanced security, trusted manufacturing and long-term supply that only Mercury can deliver.

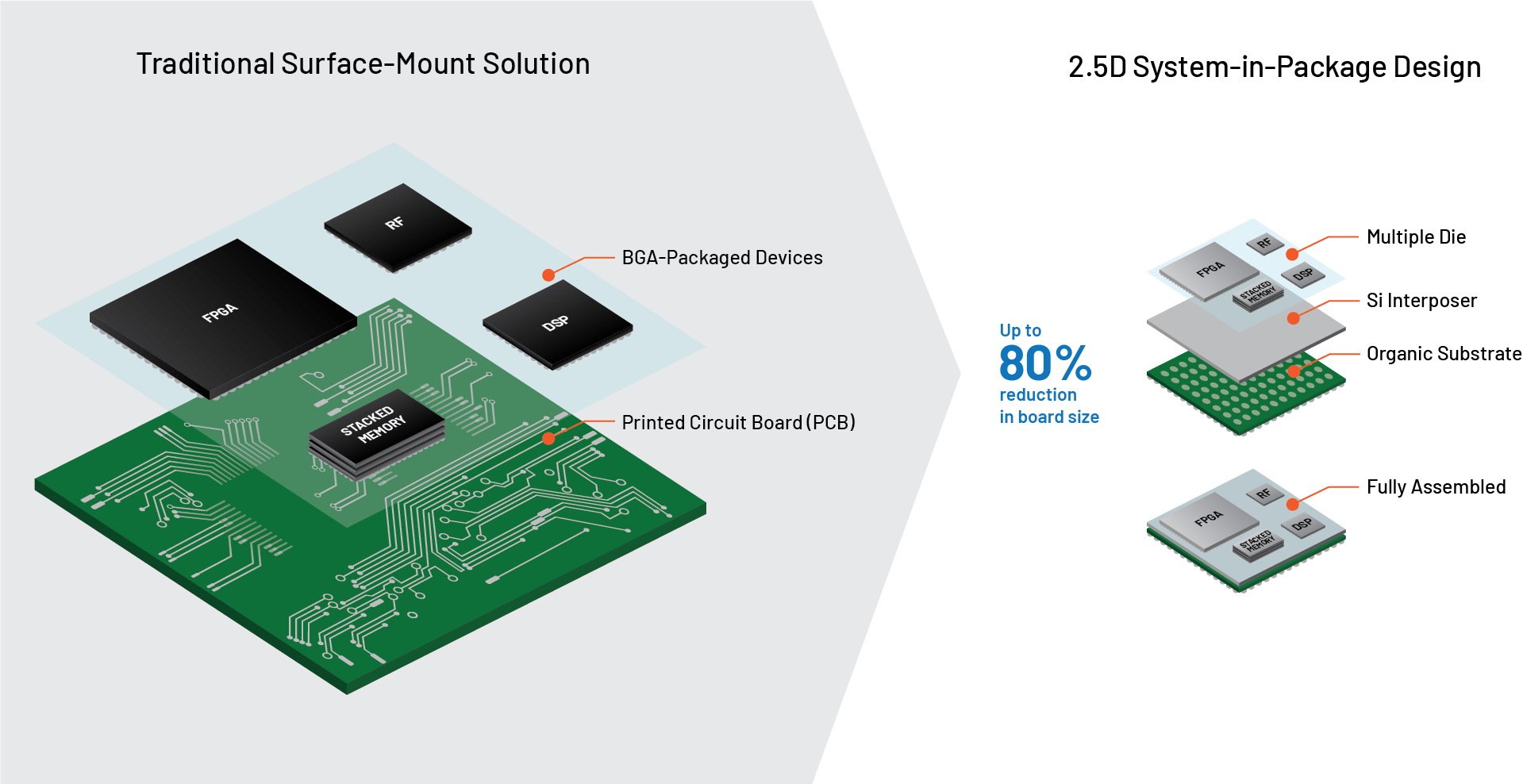

At Mercury, we make cutting-edge commercial technologies profoundly more accessible to all customers and seamlessly customize them for today’s most advanced A&D applications. Leveraging high-density 2.5D system-in-package technology, custom-designed silicon interposers and 3D die-stacking integration, we partner with leading semiconductor manufacturers to deliver advanced technology to the harshest environments.

Redefining Sensor Edge Processing

Tom Smelker, VP and General Manager at Mercury Systems, shares how 2.5D microelectronics integration in semiconductor design is a powerful new trend that will redefine edge processing in the smallest form factor possible.

TRUSTED MICROELECTRONICS

The power of our game-changing chiplet technology, coupled with our next-generation trusted microelectronics capabilities, provides up to 75% reduction in lead time, thousands of customizable configurations and reliable performance.

Learn about critical technology for next-gen army vehicle autonomous driving, navigation and...

Learn about Mercury's data recorder solutions for sophisticated technologies to manage and analyze...

In this interview, Vincent Pribble, Principal Product Manager at Mercury Systems, discusses current...

DRFM-based radar environment simulators and radar target generators are efficient, cost-effective...

Contact us to discover what's possible at the edge